Good Work

03

In a state with a large inland population, nothing is more important than supplying people with a steady flow of drinking water.

Challenge

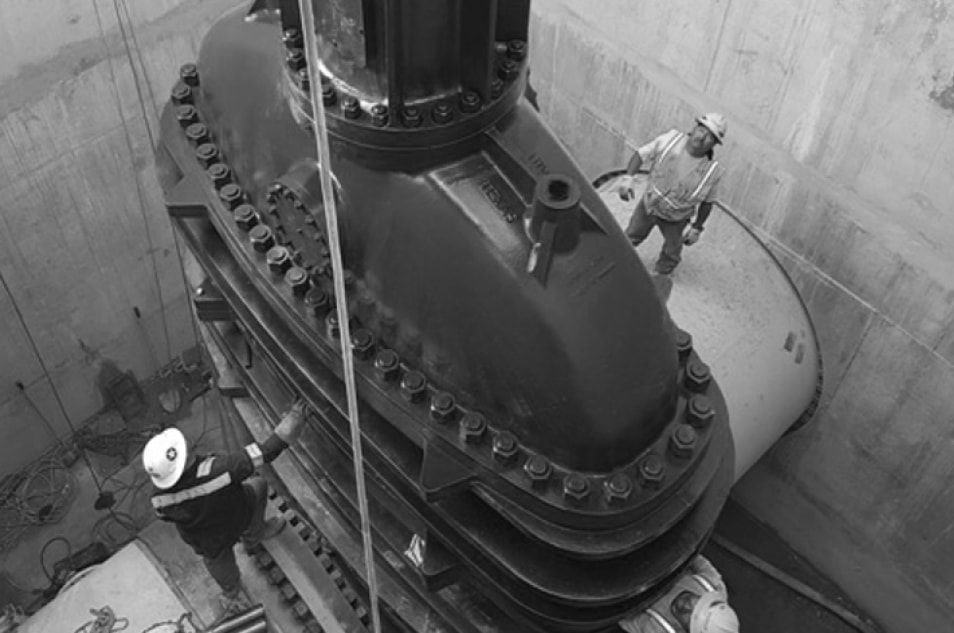

The state of Texas launched a massive infrastructure project to provide its booming population with a fresh supply of clean drinking water, and our company was tasked with assembling and testing the world’s largest gate valve, a 108" valve, as a part of the initiative. The completed valves would help regulate the powerful force and flow of water through sections of the pipeline. With a higher lifting capacity and deeper experience than most facilities, our shop was better equipped to do the job.

The state of Texas launched a massive infrastructure project to provide its booming population with a fresh supply of clean drinking water, and our company was tasked with assembling and testing the world’s largest gate valve, a 108" valve, as a part of the initiative. The completed valves would help regulate the powerful force and flow of water through sections of the pipeline. With a higher lifting capacity and deeper experience than most facilities, our shop was better equipped to do the job.

Process

Assembling a valve of this size was a tough and tall order that required a great deal of planning and precision. Working closely with the engineering team, we assembled and tested five 108" gate valves in a matter of months. We ensured that the valves met the most exacting standards, expertly handling large, heavy subcomponents with 90 ton cranes at our facility.

Assembling a valve of this size was a tough and tall order that required a great deal of planning and precision. Working closely with the engineering team, we assembled and tested five 108" gate valves in a matter of months. We ensured that the valves met the most exacting standards, expertly handling large, heavy subcomponents with 90 ton cranes at our facility.

Strategy

Throughout the assembly and testing process, we were required to inspect at hold points for dimensional accuracy. The test itself required 12,000 gallons of water that produced 375 psi during the test. All of the 108" valves assembled at Davis passed the required tests. With the job complete, we disassembled the valves and loaded out for shipping. We were humbled to play a part in a legacy project that will serve the people of Texas for decades to come.

Throughout the assembly and testing process, we were required to inspect at hold points for dimensional accuracy. The test itself required 12,000 gallons of water that produced 375 psi during the test. All of the 108" valves assembled at Davis passed the required tests. With the job complete, we disassembled the valves and loaded out for shipping. We were humbled to play a part in a legacy project that will serve the people of Texas for decades to come.

Highlights

Capabilities/Process

Assembling and Testing of a Completed Valve & CNC Machining as Well as Painting The Entire Valve

Delivery

Four to Six Weeks Once All Parts Were Ready

Standards

AWWA

Industry for Use

Water

Material

Ductile Iron

Volume

5